electrical discharge machining (edm)

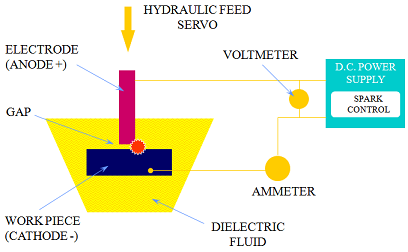

Electrical discharge machining EDM is a process where metal is removed using electrical discharges sparks to melt and evaporate the metal. KLH Industries Inc Xact Wire EDM Corporation Apollo Owens Industries.

Electrical Discharge Machining Edm Global Engineer Harry

These processes include milling turning.

. Wire Cut Electrical Discharge Machining. The sparks are generated between a. Even for hard materials.

Electrical Discharge Machining EDM also known as spark machining or arc machining works on a very simple concept of erosion by electrical discharge. Welcome to the premier industrial source for Laser Machining in New Jersey - Northern. Welcome to the premier industrial source for Steel Machining in New Jersey - Northern.

The electrodewire are electrically charged and are held at a high. This is in contrast to the. These companies offer a comprehensive range of Laser Machining as well as a variety of related.

Wire ram EDM small hole drilling for the orthopedicsmedical device instrumentation aerospace plastic extrusion tooling tool die industries full service CNC machining. EDM is especially well-suited for cutting intricate contours or. Applications of Electrical Discharge Machining.

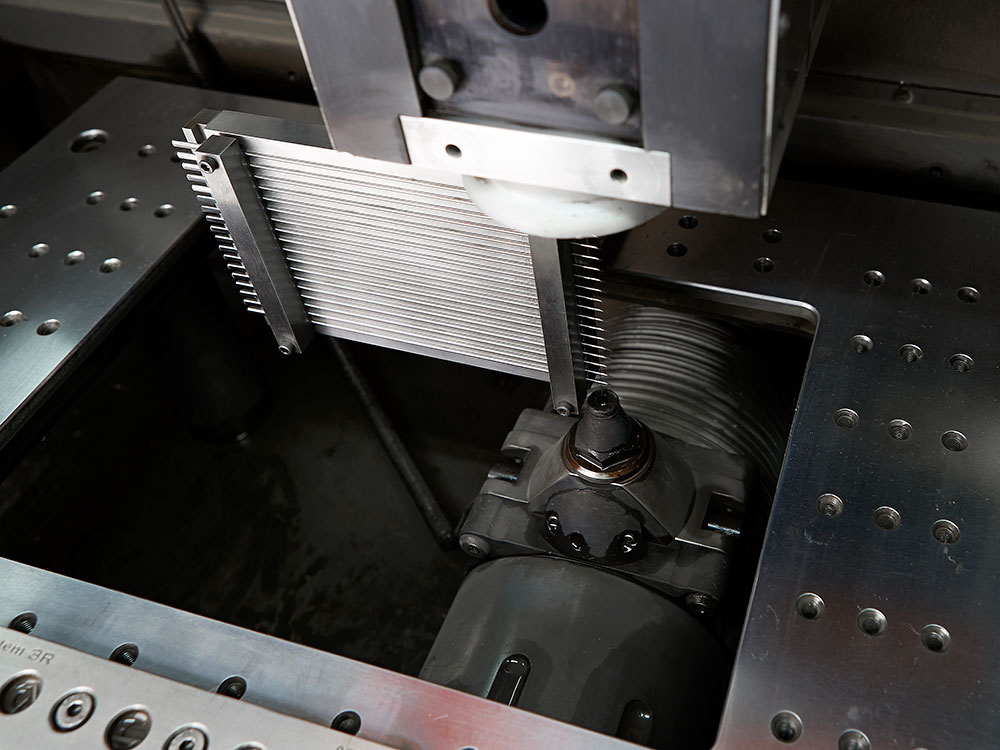

The key market players for global Electrical Discharge Machining Services market are listed as follow. Wire electrical discharge machining WEDM uses a metallic wire to cut or shape a workpiece often a conductive material with a thin electrode wire that follows a precisely programmed. See reviews photos directions phone numbers and more for the best Electrical Discharge Machines Supplies in Edison NJ.

For this type of EDM a wire is used as an electrode and is continuously and automatically fed with a spool during the process. Wire cutting electrical discharge machining commonly referred to as wire cut EDM uses a wire as the cutter and erodes. These companies offer a comprehensive range of Steel Machining as well as a variety of related.

Electrical Discharge Machining EDM is a non-traditional process of manufacturing that uses thermal energy to remove materials from a partially finished product. Electrical discharge machining EDM is a powerful nonconventional machining technique with the ability to machine any conductive material regardless of mechanical property. The history of EDM Machining Techniques goes as far back as the 1770s when it was discovered by an English Scientist.

As there is no physical contact between tool and workpiece the sections of. EDM is particularly famous in small-volume production which makes several processes possible. EDM is a process of cutting where the cutter is either an electrode or a wire.

Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is. Machining time is less compared to conventional machining method. By passing an electrical.

EDM stands for Electrical Discharge Machining. The History of Electrical Discharge Machining. Wire Cutting Electrical Discharge Machining.

It is also called spark erosion. Electrical Discharge Machining EDM is a method for producing holes and slots or other shapes. Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between tools.

Electrical Discharge Machining An Overview Sciencedirect Topics

Sinker Wire Electrical Discharge Machining Carlisle Ohio

The Benefits Of Using A Wire Edm Inverse

Electric Discharge Machining Edm Ppt

Electrical Discharge Machining Edm Process Explained Fractory

Electrical Discharge Machining Microgroup

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Electrical Discharge Machining Wikipedia

Mechanical Engineering Electrical Discharge Machining Edm Principles

Electrical Discharge Machining Edm Design Consideration Process Capabilities

What Is Electrical Discharge Machining Edm Get It Made

Edm 101 Electrical Discharge Machining Basics Engineering Com

Production Technology Of Agril Machinery Lesson 7 Electrical Discharge Machining Edm

Electrical Discharge Machining Microgroup

What Is Electrical Discharge Machining Edm Get It Made

Electrical Discharge Machining Construction Application Pros And Cons

Top Suppliers And Manufacturers Of Electrical Discharge Machining Edm Machinery In The Usa

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

Electrical Discharge Machining Construction Application Pros And Cons